Top Finish Trends for 2026

Finish trends matter because they affect what's available, what looks current versus dated, and what specifiers are asking for. Here's what we're seeing come through the workshop right now.

What's growing

Brushed brass continues to strengthen. It's been building for several years and shows no sign of slowing. The warmth works with most interior palettes, it reads as premium without being ostentatious, and the brushed texture hides fingerprints and minor wear better than polished alternatives.

We're making more brushed brass now than at any point in the past decade. Commercial, hospitality, high-end residential - it's crossing all sectors.

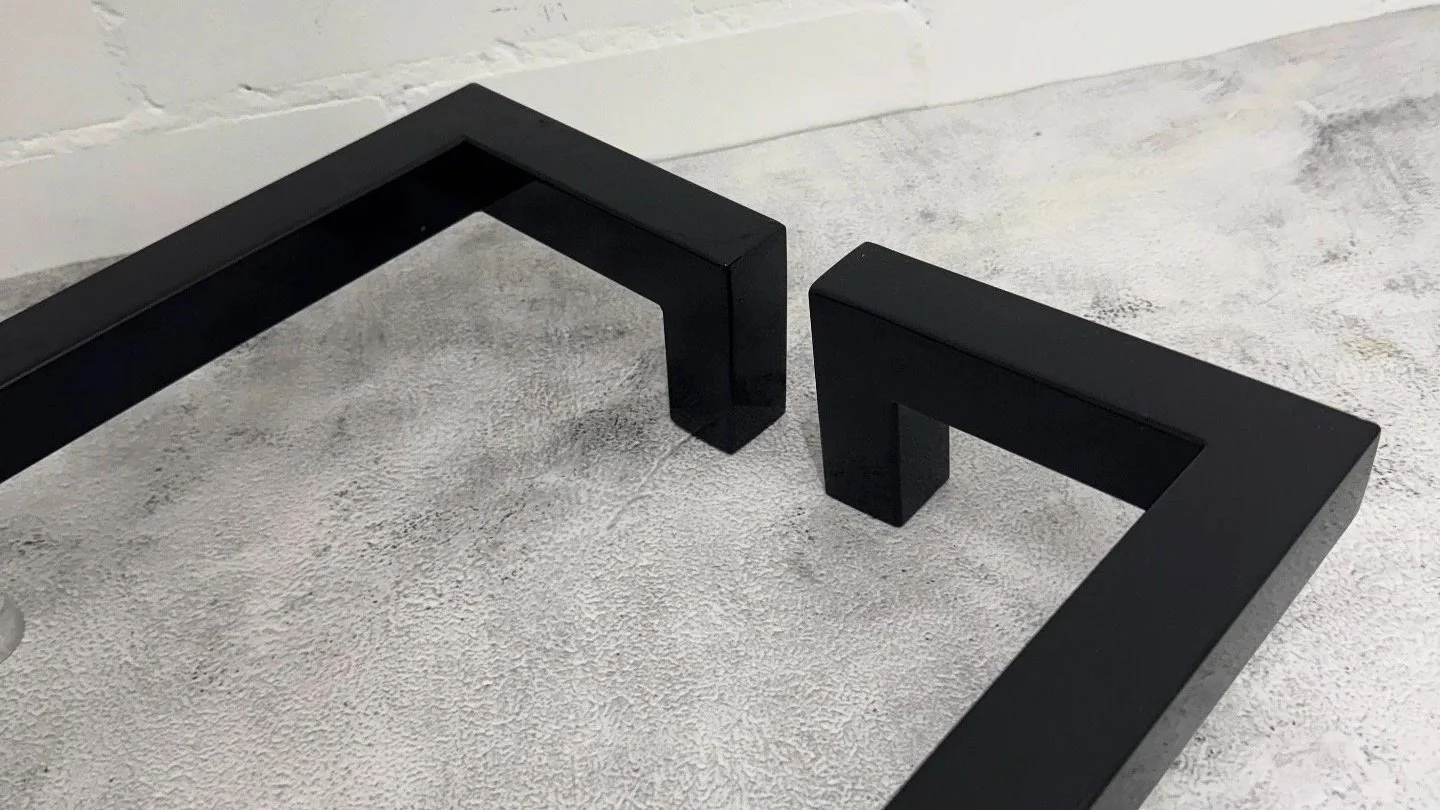

Satin black is the emerging story. Particularly strong in contemporary retail and hospitality, where it provides contrast against lighter interiors and photographs well for brand imagery. The powder coat and PVD options have improved significantly, so durability concerns that limited earlier adoption are less relevant now.

Antique bronze is returning. Heritage projects obviously, but also new builds that want established character from day one. The hand-applied patina work is labour-intensive, but the results have depth that factory finishes can't replicate.

Dark bronze more generally is having a moment. Less maintenance-visible than black, warmer than stainless, works across traditional and contemporary schemes.

What's declining

High polish finishes are falling away. Polished brass, polished stainless, polished chrome - all declining in specification frequency.

The maintenance reality has caught up. Polished surfaces show every fingerprint, every smudge, every minor scratch. They look spectacular on installation day and tired within months unless maintenance regimes are rigorous. Most buildings don't maintain that rigorously.

Chrome specifically feels dated in most applications now. It dominated commercial hardware for decades but reads as utilitarian rather than premium. Satin stainless has largely replaced it where corrosion resistance matters and aesthetics are secondary.

Bright finishes generally are giving way to surfaces that perform as well as they look. The shift is toward finishes that age gracefully rather than finishes that fight against ageing.

Sector-specific patterns

Hospitality is driving much of the brass and bronze growth. Hotels understand that hardware is part of the guest experience, and warm metallic finishes contribute to the atmosphere in ways that clinical stainless doesn't.

Retail is split. Premium retail follows hospitality toward brass and bronze. High-volume retail still favours stainless for durability and maintenance simplicity. Fast-fashion and food retail are adopting satin black where brand guidelines support it.

Commercial office is conservative. Satin stainless remains dominant because it's safe, durable, and acceptable to diverse tenant requirements. Premium office developments are beginning to incorporate brass in reception and lift lobby areas where differentiation matters.

Heritage continues its own trajectory. Antique bronze, dark bronze, and brass patinas for listed buildings and period properties. The requirement here is authenticity, which means hand-finished work that matches or complements existing metalwork.

Finish selection beyond aesthetics

Choosing a finish isn't just about what looks right today. It's about what will look right in five years, what maintenance is realistic, and how the finish performs in its specific environment.

Brushed finishes hide wear better than polished. Darker finishes show dust more than lighter ones. Some finishes require specific cleaning products. Some develop patina intentionally; others develop it as deterioration.

Coastal and pool-adjacent environments limit options regardless of preference. Marine-grade stainless or appropriate coatings become necessities rather than choices.

High-traffic areas need finishes that handle heavy use without showing every contact. Reception desks and retail entrances see more touches per day than most residential hardware sees in a year.

The direction overall

The market is moving toward practical beauty. Finishes that look good and perform well over time, rather than finishes that prioritise one at the expense of the other.

This favours quality manufacturing. Premium finishes applied properly last longer and age better than budget finishes that look similar initially. The gap between them widens over years of use.

It also favours British manufacturing for commercial projects. Being able to see and adjust finishes directly, to match samples against existing metalwork, to develop custom finishes for specific requirements - these capabilities matter more when finish selection is more demanding.

The trend toward more considered finish specification is good for projects that take hardware seriously. It produces better outcomes for buildings and the people who use them.